"Mikimoto Jewelry" was born in the Meiji era as a jewelry production factory for "Mikimoto". The magnificent Tiara, with its superb technology, is a culmination of craftsmanship that has been handed down for over a century. "La Flore de MIKIMOTO (La Flore de Mikimoto)" tiara which is a crystal of craftsmanship, completed by about 30 artisans over a year. We will deliver the story of the birth of this high jewelry along with the Japanese commentary of INTO JAPAN original.

"It takes ten years to work late, so flowers bloom in great ways."

Kokichi Mikimoto, who succeeded in cultivating semicircular pearls in 1893, took 10 years or more to make it a true circle. Kokichi, who finally succeeded in cultivating true circle pearls in 1905, has left the words, "It takes a long time to work, and how to bloom flowers." The forgiving spirit has not changed in jewelry making.

Road to the Royal Jeweler

Prince Akihito Komatsumiya, who visited Europe for the coronation ceremony of King Edward VII in 1902, visits a jewelery store in Paris with the cultured pearls of "Mikimoto", and converts it into a beautiful accessory and takes it home. Kokichi Mikimoto, who admired them, was impressed by the wonderfulness of the work and decided to put cultured pearls into first-class jewelery by himself and put it out to the world.

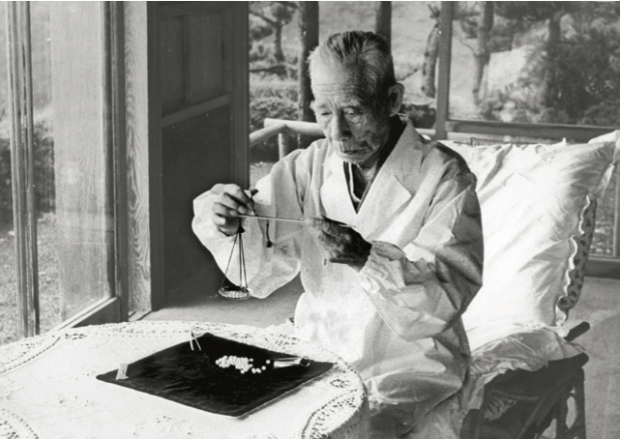

"Shinjukaku" was the residence of Kokichi Mikimoto at Tatoku Aquaculture Farm in Shima, Mie. In 1951, Kokoshi, a 93-year-old who weighs pearls.

"Shinjukaku" was the residence of Kokichi Mikimoto at Tatoku Aquaculture Farm in Shima, Mie. In 1951, Kokoshi, a 93-year-old who weighs pearls.

In 1907, when the craftsman's workshop which had been asked for work for a long time was purchased together with the craftsman, "Mikimoto goldsmith factory (now Mikimoto accessories)" was established to take charge of the production department of "Mikimoto". The factory, which was launched by just nine people, has successfully integrated the advanced technology of the West with the metal craftsmanship that Japan boasts, and has established a creative jewelry craftsmanship. Even now, it is a technique developed and introduced from Europe and the United States, "Caliblable clasping" which put square cut stone tightly and beautifully embellished "Pulp", which beautifully embellish the jewelry of "Mikimoto". Kokichi Satoshi, who had already set its sights on entering the world, worked to further improve the technology by dispatching artisans overseas.

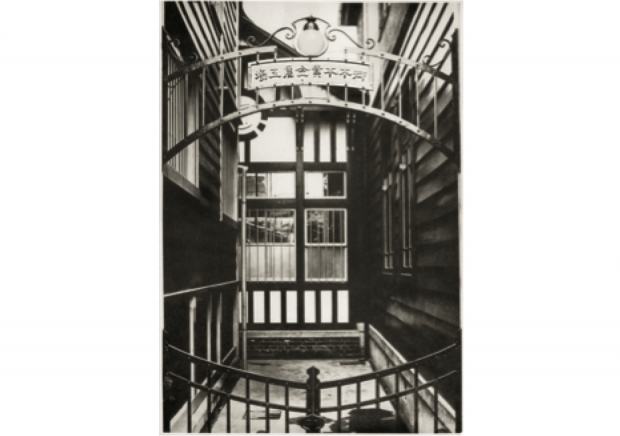

The "Okimoto Gold Works" moved from Tsukiji to Uchiyukicho for expansion the year after its founding in 1907. It was renamed "Mikimoto Precious Metal Factory" in 2013.

The "Okimoto Gold Works" moved from Tsukiji to Uchiyukicho for expansion the year after its founding in 1907. It was renamed "Mikimoto Precious Metal Factory" in 2013.

Then, in 1915, "Mikimoto" is the great master of the Emperor Taisho and receives the production of the chest ornaments of Empress Tsumeaki. Two years later, I made my first tiara. Tiaras need to be beautiful from all angles, yet light and functional. It requires skill and experience, and there is a Tiara workshop in Paris, home of jewelry. It was also a proof that high technology was recognized when “Mikimoto” was asked to produce it while the royal costume accessories were almost made in foreign countries.

In January 1924, “Mikimoto” overcomes the Great Kanto Earthquake of the previous year and produces a set of wedding accessories including the tiara of the royal prince, Princess Ryoko, in the marriage of Emperor Showa, who was the prince. Full payment by. In the same year, "Mikimoto" turned the gold signboard of Miyauchi orders and finally became a formal "Royal Jeweler". Tiara continues to be a special jewelry for such "Mikimoto".

Tiara named "La Flore" which means "goddess of flowers" in French

About a year or more was spent on completion. "La Flore de MIKIMOTO (La Flore de Mikimoto)" Tiara [Akoya pearl (about 5.5 ~ 9.75mm) ✕ pink & white diamonds total 106. 76ct ✕ WG] Reference product (Mikimoto)

About a year or more was spent on completion. "La Flore de MIKIMOTO (La Flore de Mikimoto)" Tiara [Akoya pearl (about 5.5 ~ 9.75mm) ✕ pink & white diamonds total 106. 76ct ✕ WG] Reference product (Mikimoto)

"This tiara that image of" the goddess of flowers "was designed with inspiration from" Venus birth "and" Spring "drawn by Botticelli, a representative artist of Renaissance Italy. Shaking flowers and ribbons Kunihiko Akiba, who is an honorable master of "Mikimoto Accessories", who is a three-dimensional figure and expresses the "soft wind" drawn in those masterpieces I will tell you.

Work to cut out parts one by one from metal with a thread saw (a cousin).

Work to cut out parts one by one from metal with a thread saw (a cousin).

In addition, this Tiara is a collection of craftsmanship that "Mikimoto" boasts. In addition to traditional techniques such as "calibrasable", "milling" and "poppy", advanced craftsmanship is also used by specialized craftsmen such as "Trembran" where the petals are delicately swayed by tiny springs. In order to express a realistic texture, the flower is produced by assembling petal and flower core into parts. The leaves are set on the back of the flower, making it a tiara with a three-dimensional effect that is beautiful from anywhere from 360 degrees.

A poppy pearl is rubbed with a file to make a surface, and it is set on a metal plate without gaps.

A poppy pearl is rubbed with a file to make a surface, and it is set on a metal plate without gaps.

"Mill strike" which sculpts a minute grain on the edge of the metal using several types of tine.

"Mill strike" which sculpts a minute grain on the edge of the metal using several types of tine.

Akiba who made silver model called modeling from design drawing and took command of completion until completion says that he wanted to convey advanced craftsmanship to future generations in the production.

"Although Tiara manufactures things for weddings, the opportunity to work on a masterpiece so far is extremely rare, and it is a good opportunity to pass on technology to young people, so the plant worked together. About 30 artisans from 20's to 60's took charge of each part, and it took about a year or more to complete using the latest CAD technology by traditional workmanship technology and computer.Tradition and advanced technology I think that it is a style unique to Mikimoto. "

Japan's unique craftsmanship not less than the West, with the aim of Kokichi Mikimoto, founder of Mikimoto. It has been over a century old, and it can be said that a large flower has just come to bloom.

Contact: Mikimoto Customer Service Center 0120-868-254

Sentence / Fukuda Yumiko shooting / Karasawa Mitsuya (Pile Driver) web configuration / Kubo Shihoko ※ WG in the text represents white gold and ct represents carat.